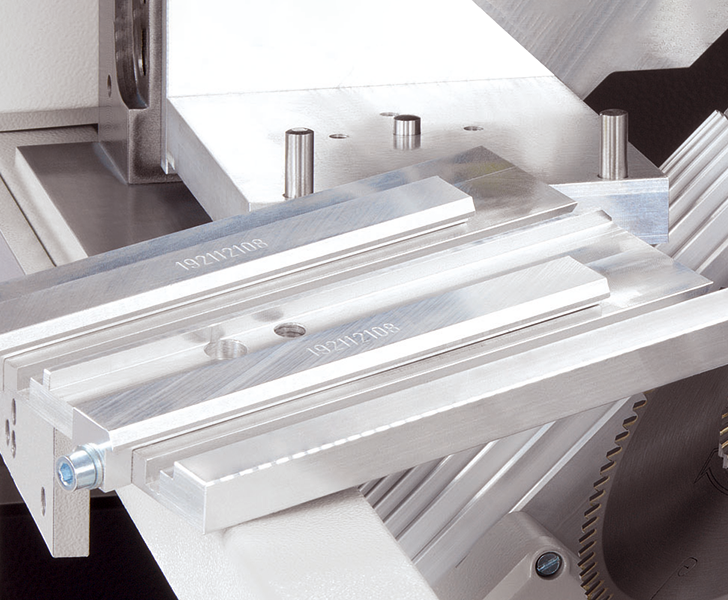

Snap-in interchangeable counterblocks

The counterblocks are very easy to change: a snap-in mechanism enables them to be changed without having to use any other tools.

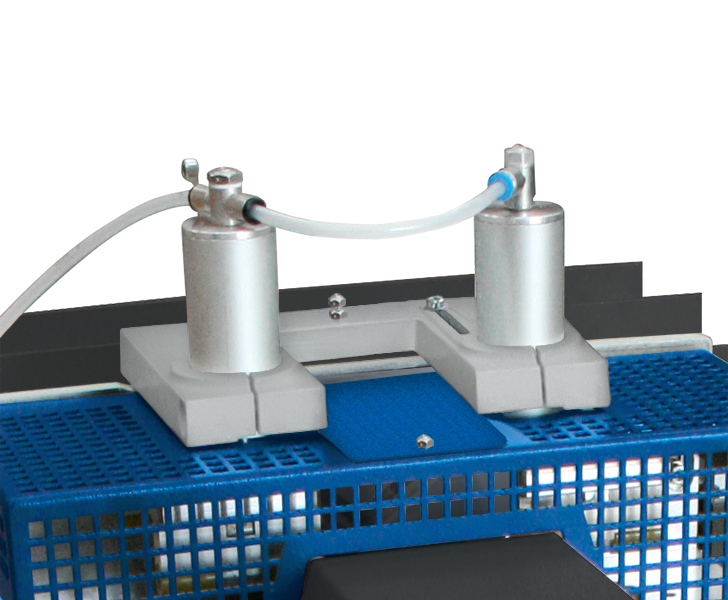

Workpiece clamping system

The workpiece is clamped from above by means of clamps; thin profiles can also be clamped by GLS 192 from the bottom to avoid the risk of deformation and to ensure a greater cutting precision.

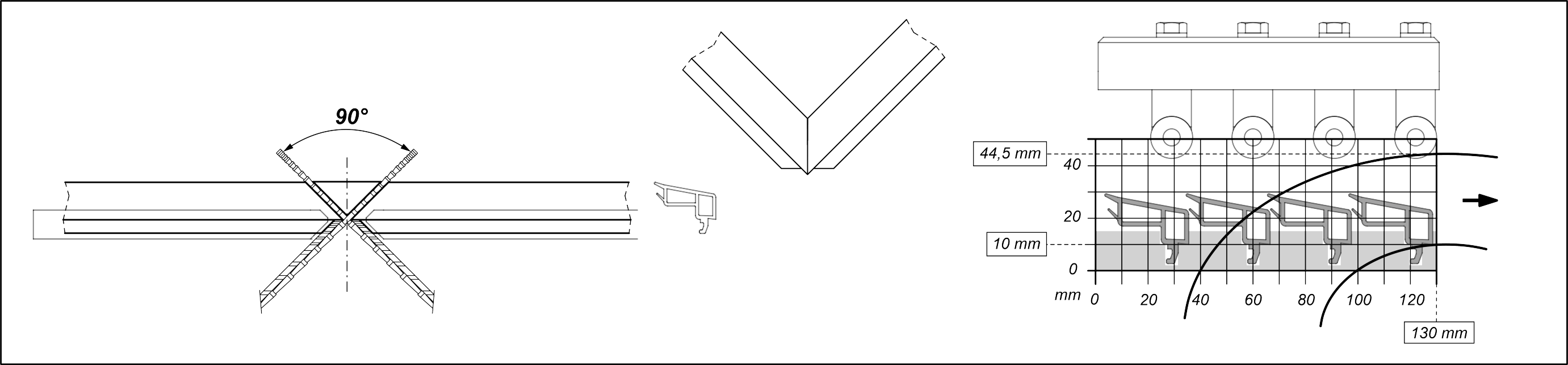

Cutting module

Glass stopper cuts are made by 2 cutting units, one set at 45° and the other at 135°. Each cutting unit is made up of 2 blades: the first actually cuts the glass stopper and the second, which has a smaller diameter, makes the cut in the glass stopper that is to house the gasket. This machine configuration enables 2 profiles to be inserted in the counterblocks so that 2 glass stoppers can be cut at the same time.

Connection to roller conveyors and stop gauges

Beside the cutting area there is a steel support for connecting the machine to an infeed roller conveyor or a stop gauge that ensures high positioning precision while cutting the glass stopper.